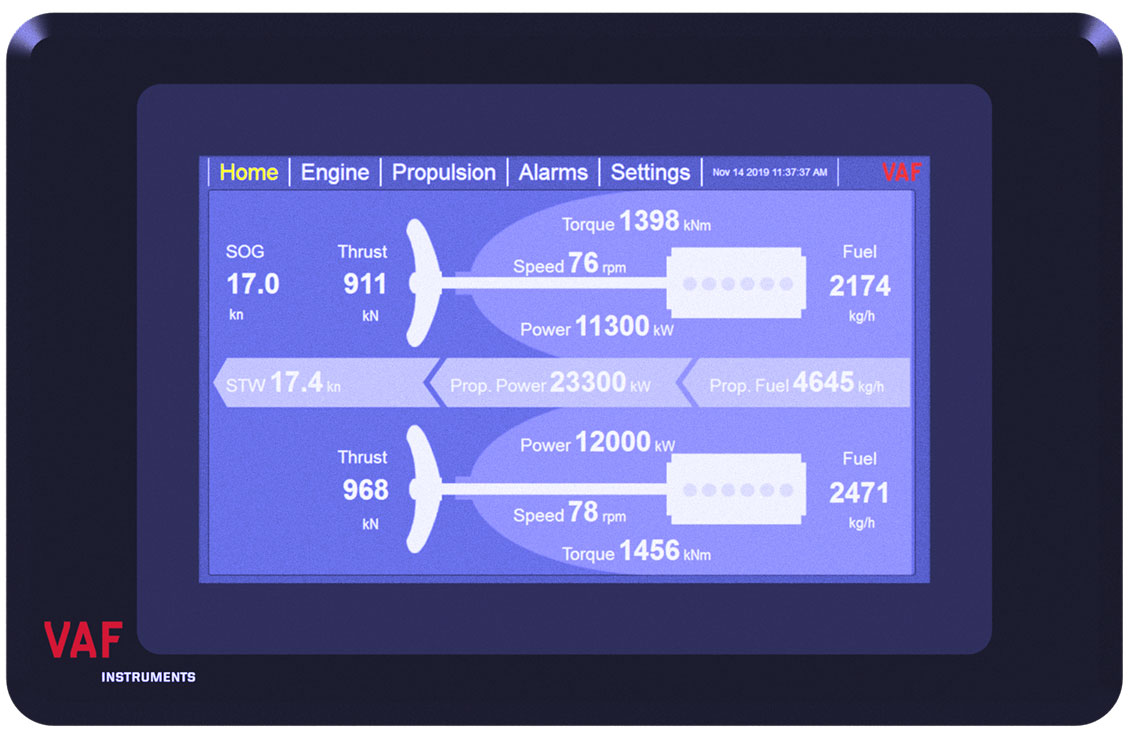

In general fuel is bought in metric tonnes. Therefore, to be consistent, fuel consumption is preferably monitored in kilograms. Smart usage of existing components of the fuel system in combination with an upgrade of the viscosity sensor enables mass flow measurement.

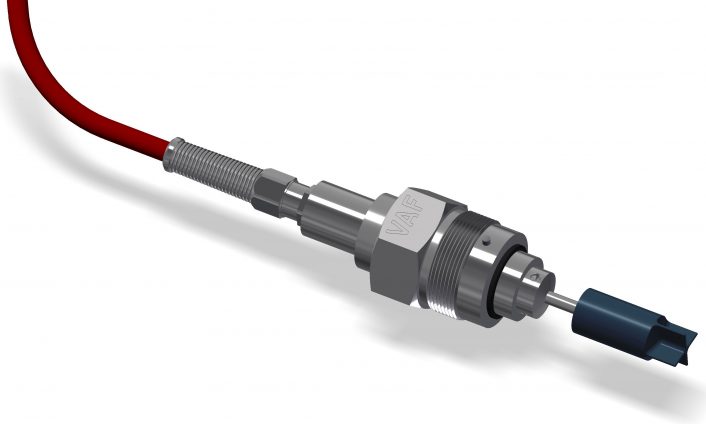

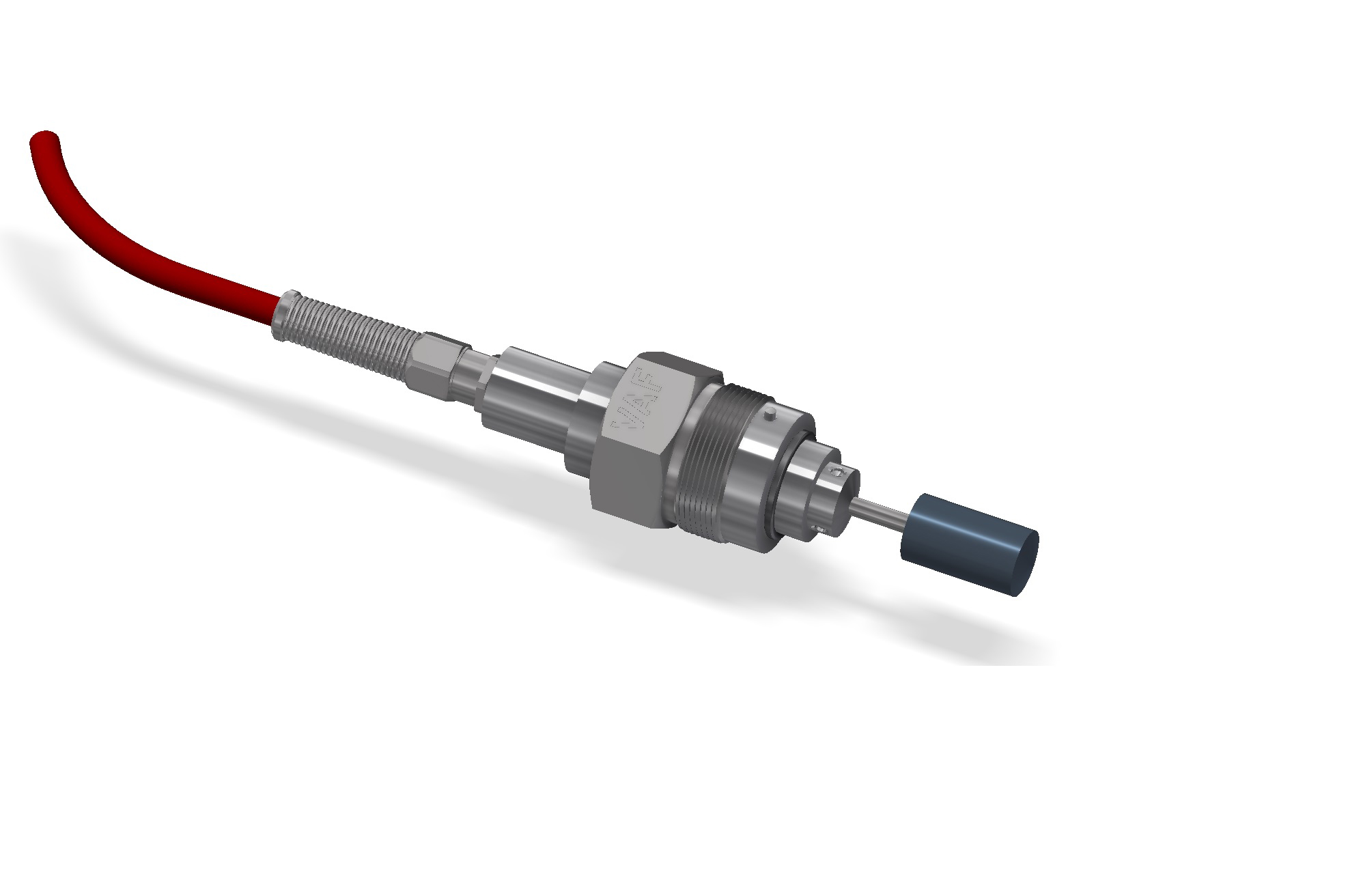

ViscoSense®3D is a highly accurate viscosity and density sensor with a superior measuring principle. The patented measuring principle of ViscoSense®3D is based on a torsional vibration of a pendulum in liquid. The measured damping of this piezo-driven vibration is directly related to the viscosity. A built-in temperature sensor is used to measure the temperature at the same location where the viscosity is measured. The sensor head is equipped with a cross vane through which a small amount of fluid is increasing the mass moment of inertia. The frequency of the pendulum, which is dependent on the mass moment of inertia, is now directly related to the density of the fluid.

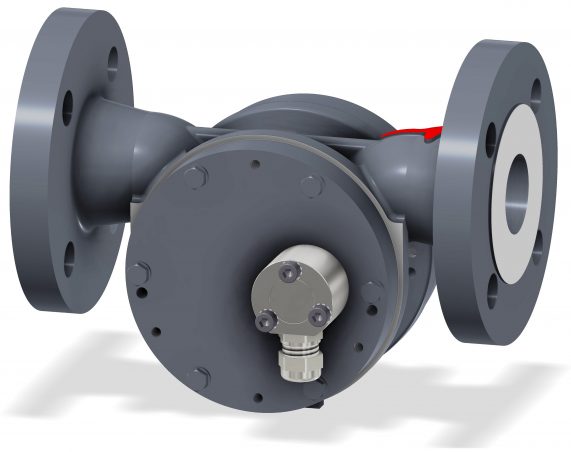

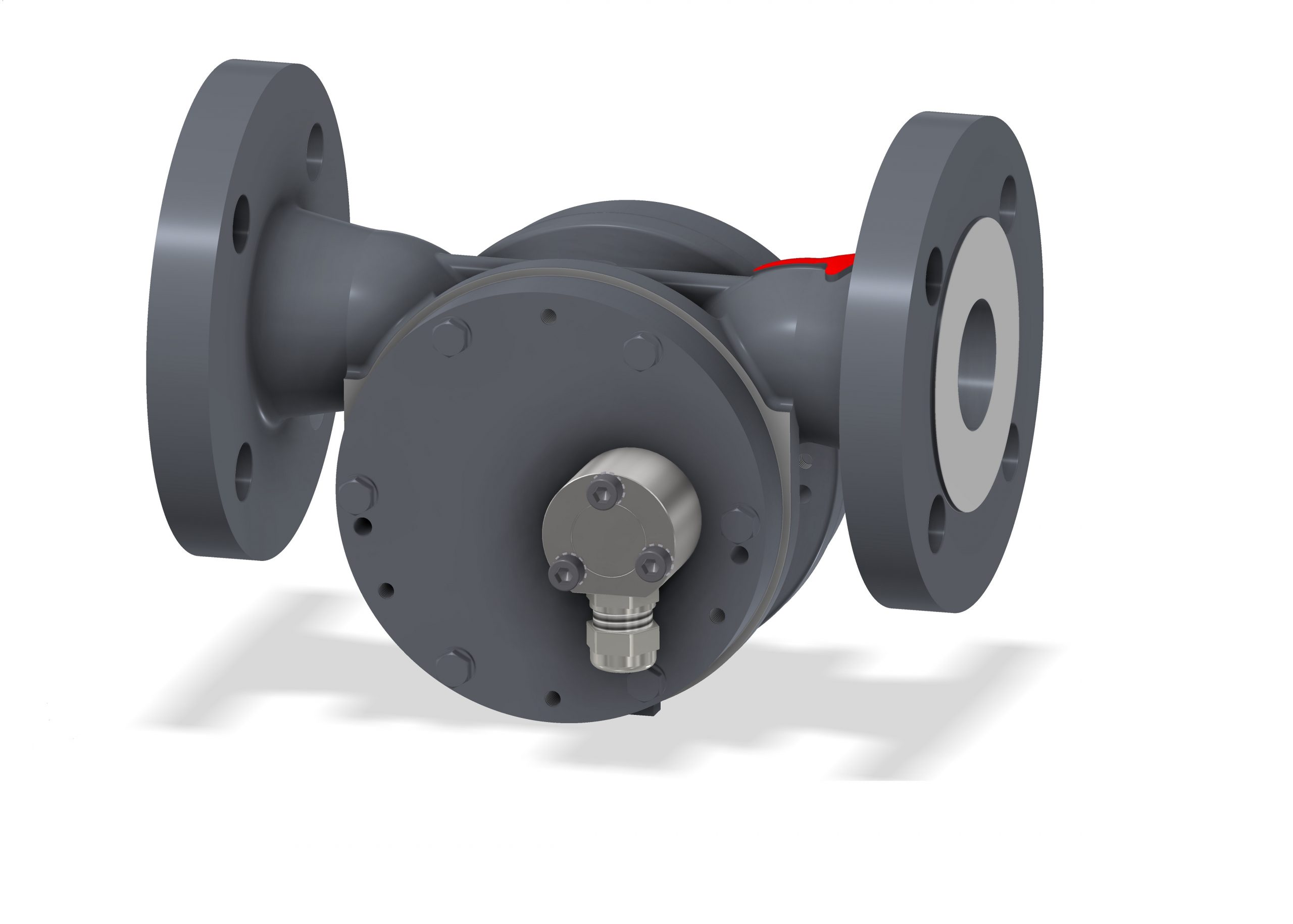

PT2-type flowmeters form the most accurate flowmeters for the application onboard ships. With mounted PT100 element for temperature compensation and high accuracy down to+0,2% they are insensitive to frequency and can be maintained in-situ. When combined with VAF Viscosense®3D (measurement and control of the viscosity and measurement of density), fuel consumption in mass can be obtained automatically, in real time.