KANON Loading Equipment is a first-class supplier on the international market for Marine, Rail and Road liquid transfer systems.

KANON distinguishes itself by designing according to the latest development with regard to efficient design, safety, ultra-low maintenance and operator convenience.

Their Arms are used from customers in all areas of the processing industry including chemical, petrochemical, storage terminals, pharmaceutical, healthcare and more.

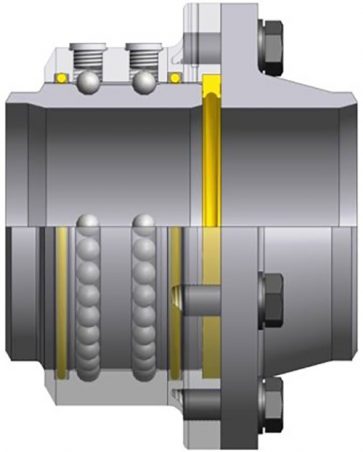

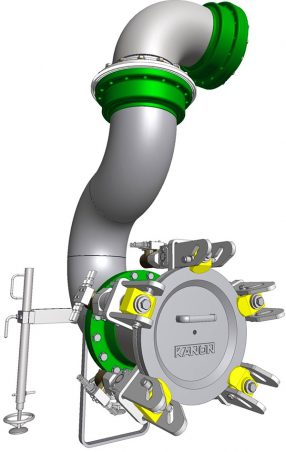

The Marine Loading Arms are of self-supporting type (MLA260) and are executed with a rigid pantograph balancing construction.

It is also a field proven marine loading arm, which can be manually or hydraulically operated.

Cost effectiveness & simplicity have been major parameters of this model without sacrificing functionality.

The MLA is designed around self-supporting rigid welded piping, absorbing all possible forces such as: deadweight & fluid weight load, pressure & wind load. This results in a smaller baseplate which in some cases provides a drastic benefit.

Contrary to other makers, the transportation of the MLA is done in fully assembled condition, saving time thus money during site erection. After the factory tests (that includes checking of settings in accordance with the specifications), the MLA is packed fully assembled on truck without any changes to its settings. This means that after arriving on site the MLA can be lifted directly from the truck onto its prepared foundation, after which the arm has to be fastened only. This has the advantage that time consuming assembling, leak test or calibration work on site is not necessary. Estimated time to erect one arm 2-3 hours maximum.

They are designed and built in line with the O.C.I.M.F. 3RDedition rules and regulations, meaning that the equipment is designed for safe and convenient operation, easy maintenance and correct performance.