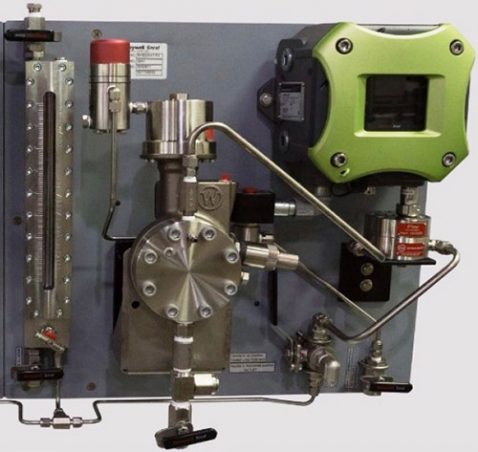

Honeywell Enraf’s Fusion4 series Additive controllers are designed exclusively to manage chemical injection, and continuously monitor the correct additive volume, ensuring the “smart” additive ratio is correct at every point in the loading transaction.

Quick start up times, calibration wizards, diagnostic dashboards and zero-downtime upgrades keep the operation moving.

Suitable for wherever there is a pressurized additive supply with a minimum 3bar differential between the additive supply pressure and main product flow pressure (with typical additive supply pressure in applications of 10bar).

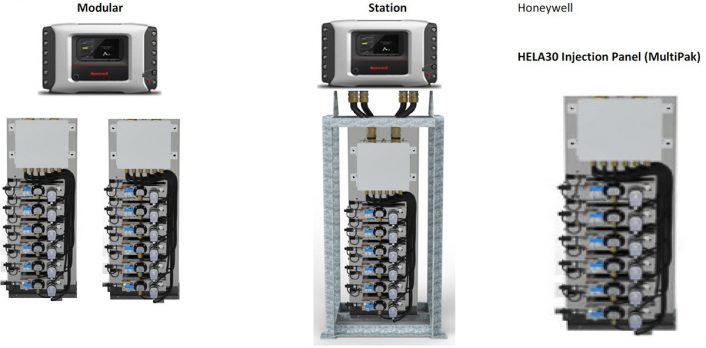

The units models are

- Fusion4 MiniPak single Stream Controller (SSC).

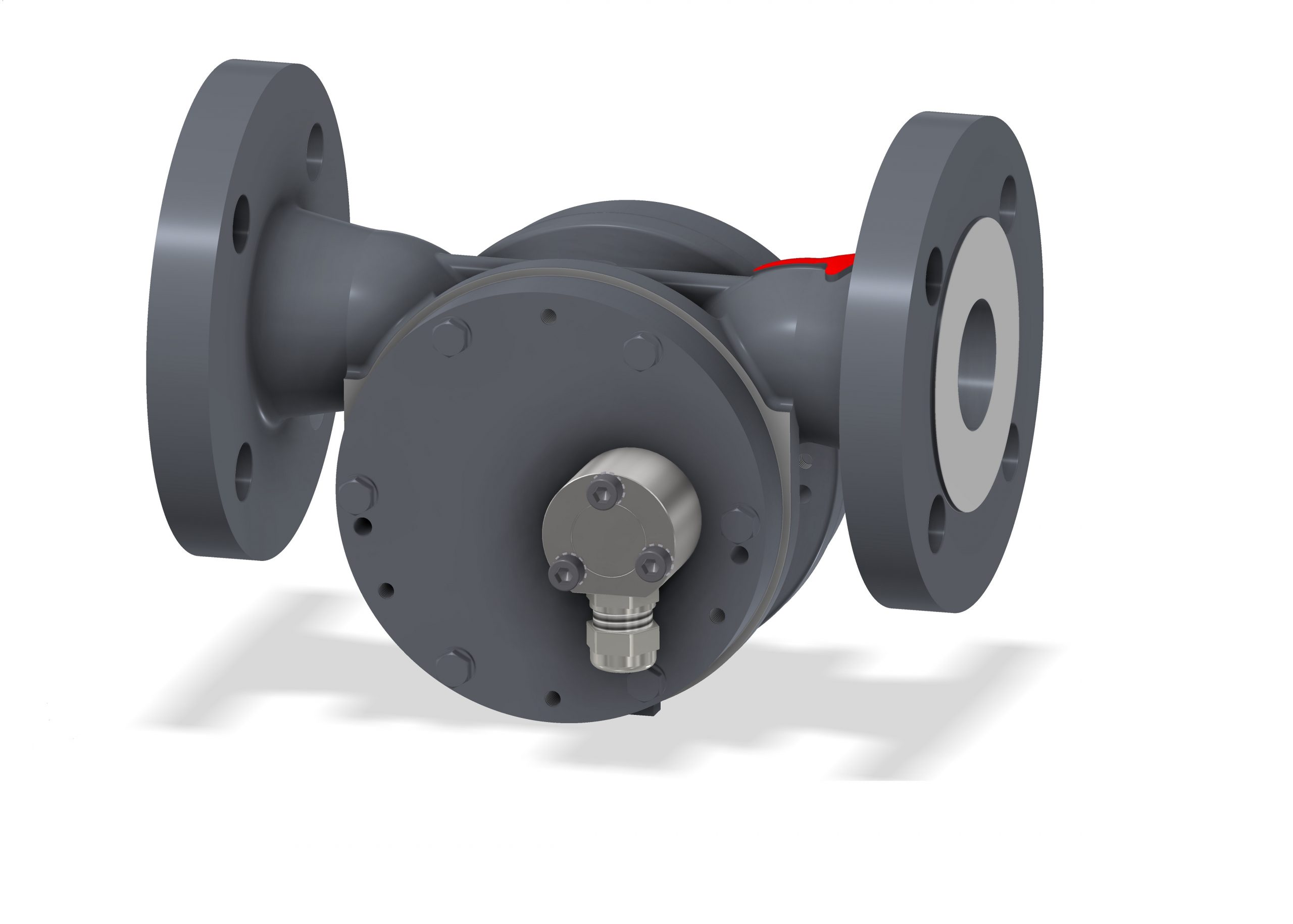

Zero in on accuracy. Combines the industry standard MonoBlock metering the most advanced hardware and the most intuitive, efficient and accurate controller on the market for precise single stream additive injection.

Benefit from intelligent features like modular I/O for scalable functionality, the Diagnostics Dashboard for rapid fault finding, a Calibration Wizard for automated W&M calibration records, and multiple language support.

- Fusion4 MultiPak multi Stream Controller (MSC).

This unit is designed exclusively to manage chemical injection, and continuously monitors the correct additive volumes across up to 12 streams (with future expandability to 24).

It features the greatest I/O density available — which combines to offer exceptional functionality and unrivalled stream control.

With enhanced information, precision and integration capabilities, Fusion4 MultiPak is part of an extensive portfolio of products which combine seamlessly.

It can be interfaced with all well known loading controllers (MSC-L, 1010, Accuload etc).