Auramarine MGO cooler units (ACU) ensure that the viscosity of marine gas oil is at a suitable level for an engine. Low-sulphur fuels, such as MGO, generally have a low viscosity and do not usually meet the minimum viscosity requirements of main engines. Viscosity can be increased by cooling the oil with our series of coolers.

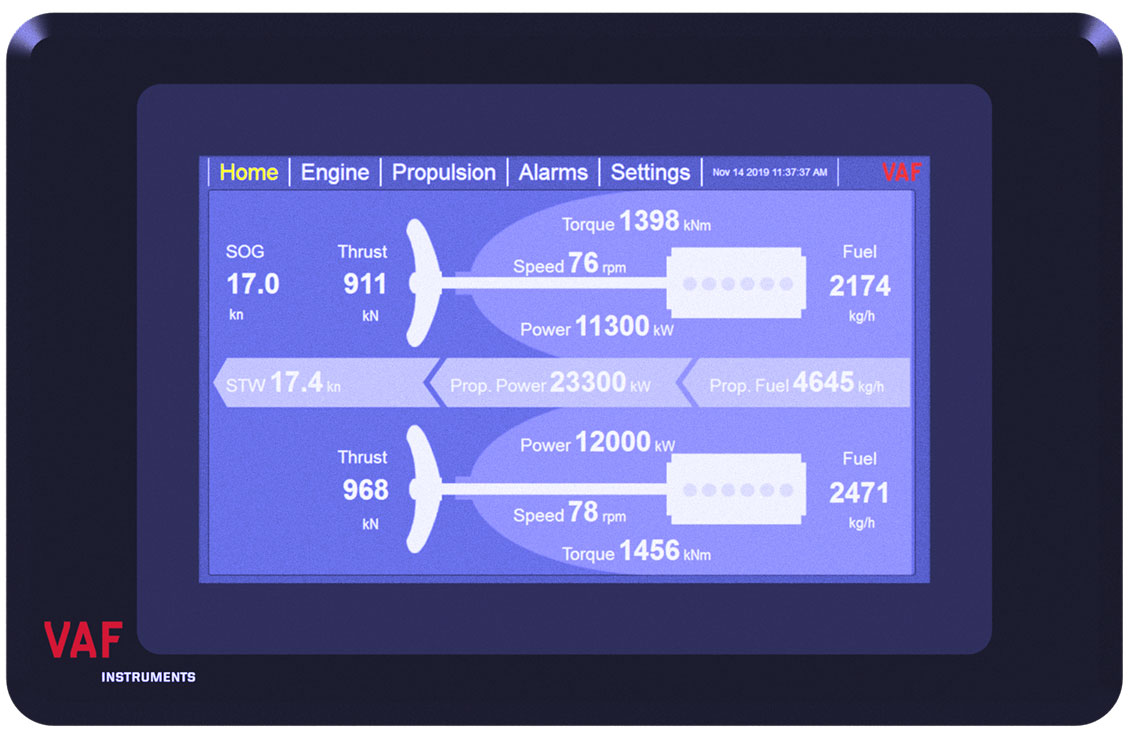

Cooler units contains a plate or a tube-type cooler, a three-way water-control valve, a temperature transmitter on the MGO outlet line for mA signal linked to the engine control room, an optional viscosity sensor (range 0-10 cSt), and all necessary fittings and valves for installation and operation.

Cooling water for ACUs is delivered from either the ship’s low temperature (LT)-water, seawater cooling system or from a separate Auramarine modular chiller (AMC) unit. The heat from the MGO fuel is transferred to the cooling water via the unit’s heat exchanger.

ACU modules have a built-in mixing function control valve, which is based on fuel outlet temperature. It controls the flow of cooling water (in LT-water models) or MGO flow (in seawater model). With this level of control, fuel temperature response is immediate and accurate. The unit’s temperature controller is factory set at a temperature change rate of 2°C/min to prevent thermal shock. This built-in feature can be brought into use with simple wired electrical connections to the changeover system or via a local manual control mode.

MGO cooler units are available as a skid-mounted module or integrated as part of an Auramarine booster unit (AMB).